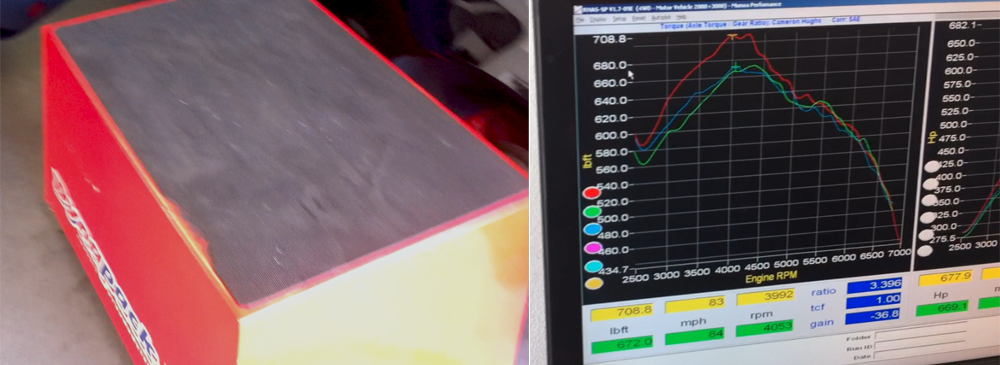

My car runs hot on the hot side because of the extra heat generated by my twin turbo set up. It’s totally within the “normal” range but the cooler your car runs the more power it’s going to make. And in the future none of my plans involved less heat so it was time for another upgrade.

I pulled out the old radiator and was shocked at how small it was! It was hard to believe it was doing much to cool the engine. A bigger radiator would definitely make a difference. Notice how little room there is in the engine bay even with the radiator out (this will play a role in my install later here).

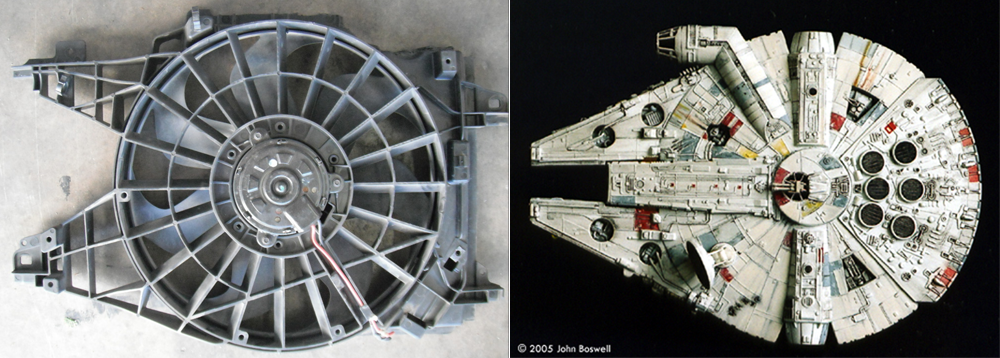

After some research I picked Dewitt’s direct fit aluminum radiator. They also offered Spal’s dual 11″ fans so I got them as well. You can see the old radiator & fan (left) next to the new set (right). The Dewitt radiator is incredibly thick compared to the stock radiator (two rows of 1″ tubes as opposed to a single row). The dual fans cover more surface area and provide more balanced cooling (every little bit helps).

The Spal fan attatches to the Dewitt’s radiator via a pair of brackets. With the help of my buddy Justin I tried to install the radiator & fan bracketed together but it was simply impossible. We put the radiator in first and then tried to slide the fan in, but it was a no go- there simply wasn’t room. In a normal set up there would be a lot of room in the front (you’d just temporarily pull out the air filter / intake) but my intercooler occupied every last bit of space. So we decided that the fan would have to go in from the bottom.

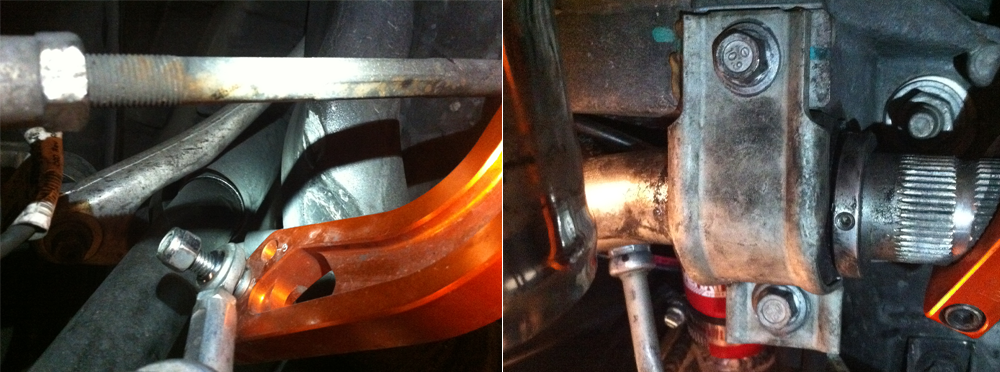

Going in through the bottom meant that I had to take out my PFADT swaybar. Taking out a sway bar isn’t a big deal (maybe a little annoying)- just remove the nut & bolt from the sway bar arms (they are generally not under tension). Next remove the two bolts from the two brackets that hold the sway bar onto the chassis. I had to to undo some of my turbo piping underneath the car too.

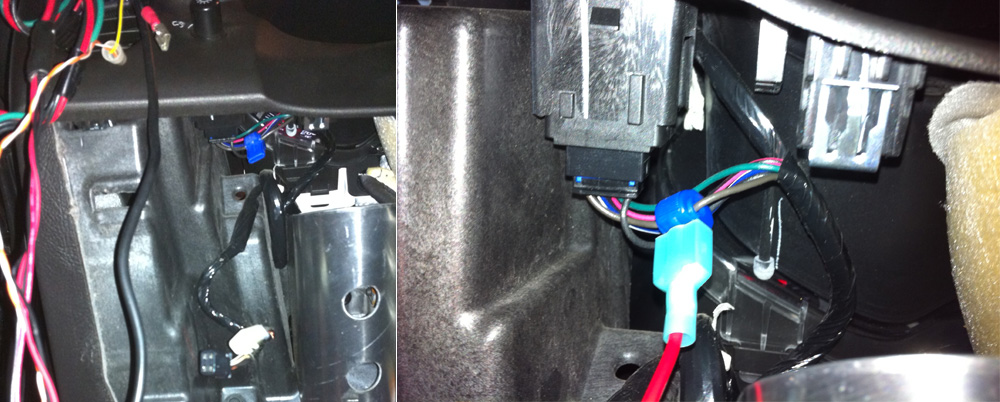

Once the sway bar was out it became apparent that the fan wasn’t going to go in easily from the bottom either. There is a bolt that comes off the ABS unit and it was in the way. The first thing I tried was cutting out part of the fan casing (you can see a notch in the pic below- I ended up having to cut out a more than that). The blades still hit a little so we ground off some of the offending bolt. That seemed to do the trick and we were able to push the fan up in place. It was tricky to get the brackets back on after the radiator & fan were installed but we managed. We spliced the Spal fans into the stock fan controller. I’ve heard arguments that this is okay and that it’s not okay. So far no issues (if a problem develops I’ll switch to a relay controlled system). Once the car was all back together we filled it up and drip… drip… drip…

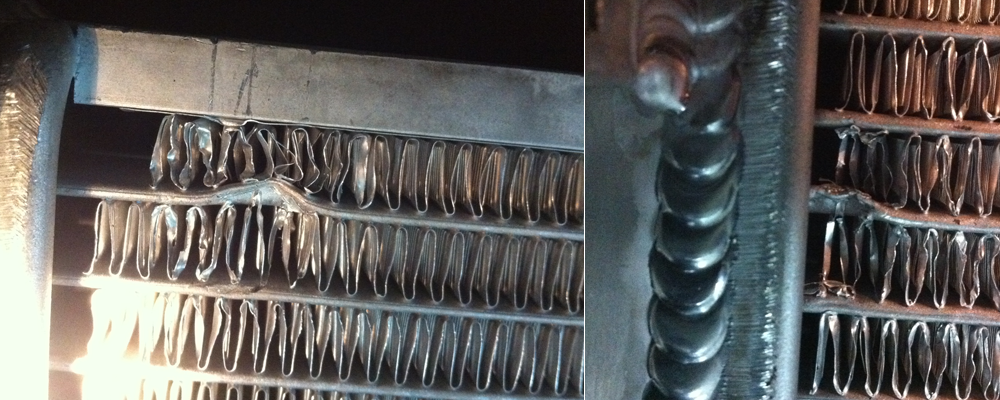

Whoops! The radiator had a leak. We pulled everything back out and inspected the damage- it wasn’t bad, but we had clearly poked two holes in the cores. It was immediately obvious what had happened- the back of the fan unit has some pretty sharp edges and they had smashed the cores as we finagled the fans in. I emailed Dewitt’s are they were very sympathetic and had me send the radiator in for repair.

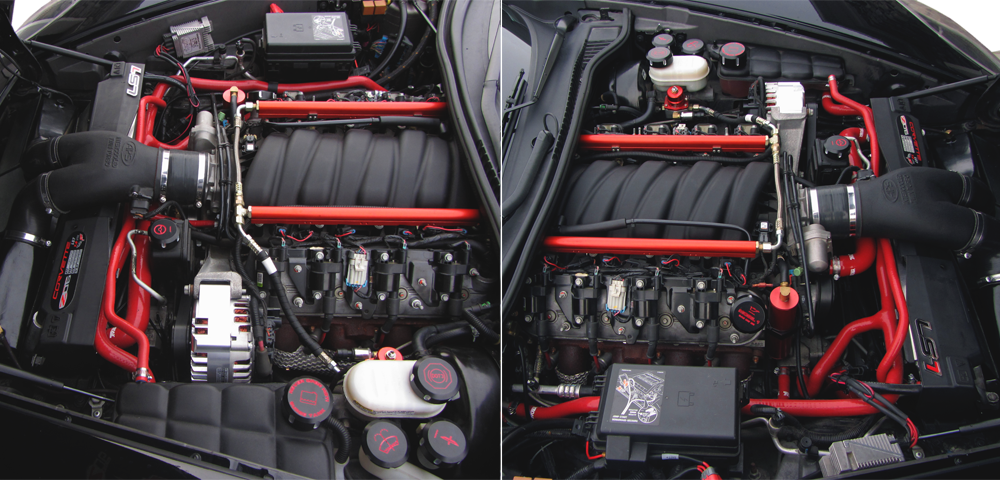

Since I had some time on my hands I decided to replace my old radiator hoses (some of them were looking pretty worn out). I picked a set of VenAir red silicone hoses to add some contrast. Everything went on with no issues except one of the heater hoses- it was just too small. I wrested with it for a long time before I gave up and contacted the seller. Turned out it was the wrong hose (Custom Corvette Accessories sent the correct hose after I contacted them- they were very responsive). I think this kit is a great aesthetic upgrade.

I got the radiator back from Dewitt’s shortly after the hoses were installed. They (Dewitt’s) were super nice. They did a great job fixing the radiator and they shipped it back to me quickly and didn’t charge me for the repair or return shipping! So, round two: We covered the the back of the radiator with cardboard to protect it when we slid in the fans. Even being super careful (and grinding down the sharp corners on the fan) you can see that we dinged up the cardboard quite a bit! We bracketed the units together, reassembled everything, filled it up and listened. Nothing. Sweet nothing.

We were almost done. The last step was to fire up the car and see how she liked it. At first things seemed to be perfect, but then the fan blades started hitting that ABS bolt again. I pushed the radiator shroud back a bit and bolted it. Still hitting. That’s when I realized that the bracket that holds the fan to the radiator has slipped forward about a quarter inch dropping the fan blades back into the bolt. Not a problem- a clip, a drill and a screw later I had rigged up a way to hold the bracket back so that the fan is pulled away from the bolt. And they all lived happily ever after.

This was a fairly big project because of the sheer number of complications that arose. Total downtime was almost a month, but I think the results are worth it. So far the car seems to run much cooler (I’ll be really curious to see how it performs once summer hits). While everything was apart I took some time to give the engine a good cleaning. Here’s how she looks right now (yes, this is my car):

Not a lot of “how to” stuff in this post (I guess you could take out your sway bar if you wanted) but if anyone has any questions about replacing the radiator (or hoses) please feel free to contact me. Also, if anyone with a similar set up (front mounted twin turbos) decides to add the Dewitt radiator & Spal fan combo I’d be curious to know how your install went and what your engine temps are like. Mod on!

Posted by Cam Hughes, Feb 19, 2012